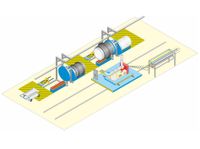

The profilline f-series extrusion line is designed for a highly flexible production and can handle a lot of different pipe diameters.

profilline f-1200: diameter range OD 355 to OD 1200

profilline f-2400: diameter range OD 800 to OD 2400

The extrusion lines can be equipped with one or two double winding stations to increase the efficiency and production capacity of the machinery. Each winding station is able to handle all sizes of pipes or mandrels within the designed diameter range. This technology is also ideal for small quantities of one order (one pipe size and profile), as you can produce different diameters and a different wall thickness on each winding station, one after another.

This is the technology you waited for: A low investment compared with conventional axial extrusion machines, combined with the flexibility and efficiency to handle smaller projects.

High inside pressure fittings

With our spiral winding technology, it is possible to extrude large diameter solid wall pipe fittings, which complement the axial extruded pressure pipes. The resin number one for this application is PE100, but the machinery will also run with modern PP grades.

The first extruded layer of the pipe is always a solid wall profile, optional with an integrated co-extruded coloured strip. The extrusion line will automatically add layer by layer, until the final wall thickness and surface structure is reached.

PE100 is number one for inside pressure, it has a high crack resistance, it is corrosion resistant, flexible and is certified for drinking water. Of course PE100 can be recycled by 100 %.

diameter range OD 355 to OD 2400

fitting length 0,5 m to 2,0 m

pressure class SDR 17 to SDR 11

output capacity up to 400 kg/h

resin: PE100 or PP