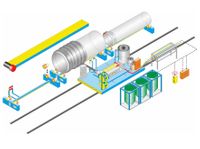

The profilline p-series extrusion line is designed for a highly flexible production. We offer two different types:

profilline p-3000: diameter range DN 300 to DN 3000

profilline p-4000: diameter range DN 800 to DN 4000

The extrusion lines can be equipped with one, two or three winding stations to increase the efficiency and production capacity of the machinery. Each winding station is able to handle all sizes of mandrels within the designed diameter range. This technology is also ideal for small quantities of one order (one pipe size and profile), as you can produce different diameters and profiles on each winding station, one after another. A solid wall pipe on station 1, a profile pipe with outside ribs on station 2 and a profile pipe with smooth inside and outside surface but an inner profile on station 3? No problem at all.

High ring stiffness profile pipes

To increase the stiffness of the pipes and at the same time to minimize the weight of the product, a structured wall pipe is the first choice. The typical profile for a pipe has a smooth inside and a profiled outside wall (picture left side). The typical profile for a manhole or a bend has a smooth inside and outside surface and an inner profile (picture rights side).

The first extruded layer of the pipe is always a solid wall profile, followed with a second layer of a hollow round chamber. The round profile is formed with a core tube (see c-series machinery), which is surrounded with PE100 or modern PP inside the extruder die head. If a manhole shaft is produced, a third layer will add another solid wall profile.

PE100 and modern PP are corrosion resistant, flexible, and certified for drinking water and can be recycled by 100 %.

diameter range DN 300 to DN 4000

pipe length 1,5 m to 6 m

stiffness values SN 2 to SN 75

output capacity up to 1.450 kg/h

resin: modern PP or PE100